Living in High Cotton

That is us, living in the 21st century. “Pretty cushy lives” compared to the limited choices our primitive forbears suffered, specifically when you consider clothing.

The various raw materials woven into the fabrics we use every day are a fascinating discovery for those who care to check labels. Natural or synthetic, and blends of these. Fibers from organic cotton or recycled soda bottles. Claims of astonishing versatility and benefits to your skin, to reassuring protection of endangered species.

For our conversation today, we are looking at cotton, the most widely used natural fiber cloth.

The Plant and Process

Gossypium, a genus of flowering plants in the mallow family, Malvaceae, is native to tropical and subtropical climates. The plant develops short-lived white blossoms about three months after planting. In their place appear green triangular pods, which are called bolls. During the next two months, seeds and seed hair (or cotton fiber) develop inside the bolls. Once mature, the bolls burst into white fluffs, each containing about ten seeds embedded in the mass of seed fibers.

The opened bolls are harvested by hand or machine. In most underdeveloped nations, cotton is still hand-picked – a labor-intensive, tiresome, and costly process. It takes about eight hours to pick a pound of cotton! However, this method generally produces cleaner cotton due to the selective capability of humans.

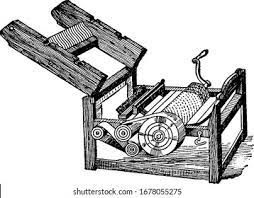

In ancient times, the seeds were also tediously removed by hand. The invention of the cotton gin (short for engine) in 1793 by the American Eli Whitney lowered cost and allowed the removal of the seeds fifty times faster than the manual process. Modern gins operate on the same principle as the rudimentary contraption Eli developed: the harvested cotton passes over a cylinder covered in sharp teeth that grabs the fiber and pulls them into narrow openings, separating the seeds from the fiber strands.

The seedless fibers are cleaned from debris, packed into bales, and shipped off to be spun into yarn and eventually woven into cotton cloth. Watch a demonstration of the original cotton gin here.

Cotton is a zero-waste product. Linters (shorter strands stuck on the removed seeds) provide cellulose for manufacturing plastics, explosives, paper products, and padding for mattresses. The crushed seeds become cooking oil, livestock feed, fertilizer, and high-protein concentrate in some food products. The stalks and leaves of the plant get plowed into the soil.

The History

Ancient civilizations in the Americas, Africa, and Asia cultivated cotton and made cloth from the strands. The fabric made its way to the Middle East and was eventually traded by Arab merchants around 800AD in Italy and Spain. In Britain, wool was king of the fabrics. Compared to cotton, wool was easier and cheaper to produce. Wealthy English were so drawn to the exotic new cloth from the tropics that the wool industry suffered economic losses. So much so that in the late 17th century, the wool barons pressured the British Parliament into signing several laws against cotton imported from India. But, the tide could not be stemmed for long. Trendy cotton quickly became how the growing middle class could display their wealth and status.

The word cotton originates from the Arabic qutun, describing any fine textile. (I love the German word for cotton: baumwolle = tree wool.) Calico, our word for plain-woven textile from unbleached cotton, got its name from Calicut, the city in India where the fabric was traditionally woven, dyed, and printed in bright colors.

The Quality

Cotton quality depends on how long the fiber strands are after ginning. The longer the thread, the finer the cotton.

The many beneficial properties of cotton products led to its mass adoption globally. Cotton cloth is durable and tear-resistant due to the plant's strong cell structure. It is soft on the skin, comfortable, and static-free. Its absorbent nature makes it a breathable fabric and an unwelcome environment for lingering bacteria.

The well-known cotton seal was designed 50 years ago. It is still a powerful influence on designers and an effective sales builder. When age-old cotton is compared to modern synthetic fibers so popular these days, it seems the verdict is still out on which fiber is superior in texture and sustainability. What do you say? Is Cotton King? For me, it is an easy yes when choosing clothes and linens. I'm very happy I live in an age where I have buying options and free access to information about the process and production of what ends up in my shopping cart.

This month Unique Batik is highlighting a wide variety of cotton garments from Thailand. Explore our wide range of comfortable flowy tops, bottoms, and dresses. And choose cotton!

Further reading:

https://www.eiu.edu/historia/Harzinski.pdf

https://www.cotton.org/pubs/cottoncounts/story/importance.cfm

https://sanvt.com/blogs/journal/the-history-of-cotton-fabric